Preparing production budgets

Mitchell Franklin; Patty Graybeal; Dixon Cooper; and Amanda White

Why we need to prepare a production budget

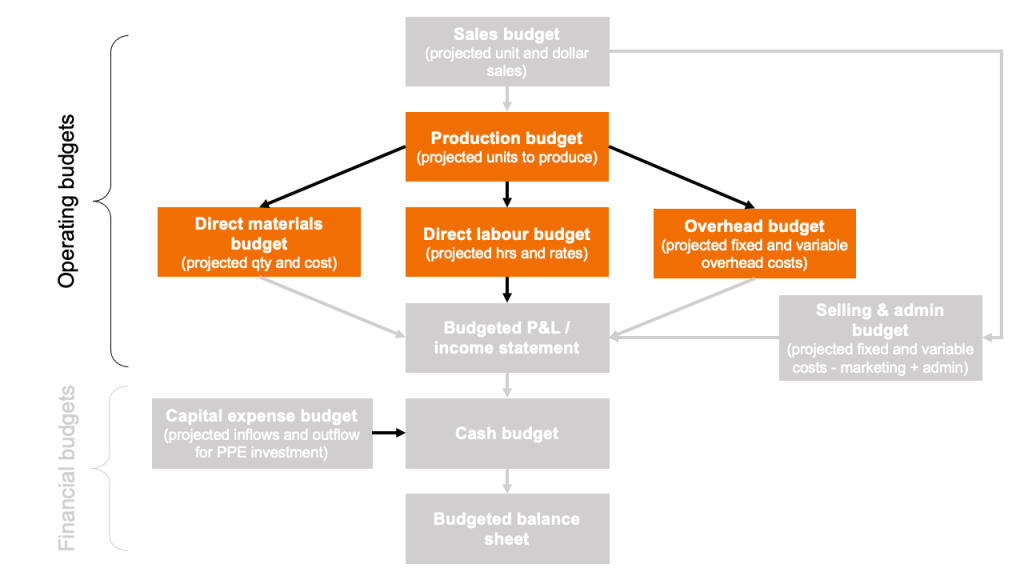

To be able to meet the demand predicted by the marketing department and management, the production or manufacturing department must be able to plan out how much inventory must be made and what components (materials, labour and overhead) will be required. A production budget plans out the inventory, and then sub-budgets related to materials, labour and overhead are produced.

In our master budget diagram, the coloured budgets are the ones we will learn how to produce in this section.

Preparing a production budget

Estimating sales leads to identifying the desired quantity of inventory to meet the demand. Management wants to have enough inventory to meet production, but they do not want too much in the ending inventory to avoid paying for unnecessary storage. Management often uses a formula to estimate how much should remain in ending inventory. Management wants to be flexible with its budgeting, wants to create budgets that can grow or shrink as needed, and needs to have inventory on hand. So the amount of ending inventory often is a percentage of the next week’s, month’s, or quarter’s sales.

In creating the production budget, a major issue is how much inventory should be on hand. Having inventory on hand helps the company avoid losing a customer because the product isn’t available. However, there are storage costs associated with holding inventory as well as having a lag time between paying to manufacture a product and receiving cash from selling that product. Management must balance the two issues and determine the amount of inventory that should be available.

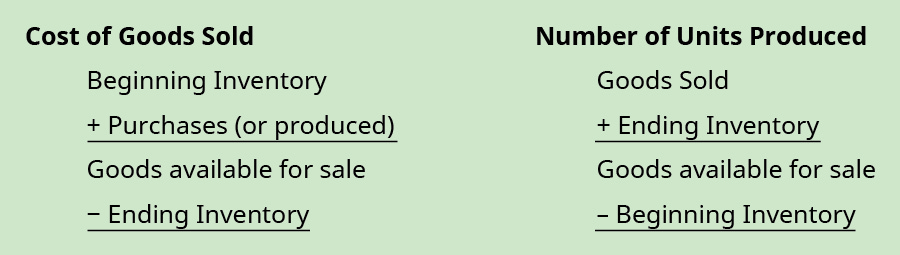

When determining the number of units needed to be produced, start with the estimated sales plus the desired ending inventory to derive the maximum number of units that must be available during the period. Since the number of units in beginning inventory are already produced, subtracting the beginning inventory from the goods available results in the number of units that need to be produced.

After management has estimated how many units will sell and how many units need to be in ending inventory, it develops the production budget to compute the number of units that need to be produced during each quarter. The formula is the reverse of the formula for the cost of goods sold.

The number of units expected to be sold plus the desired ending inventory equals the number of units that are available. When the beginning inventory is subtracted from the number of units available, management knows how many units must be produced during that quarter to meet sales.

In a merchandising firm, retailers do not produce their inventory but purchase it. Therefore, stores such as KMart and BigW do not have raw materials and instead substitute the number of units to be purchased in place of the number of units to be produced; the result is the merchandise inventory to be purchased.

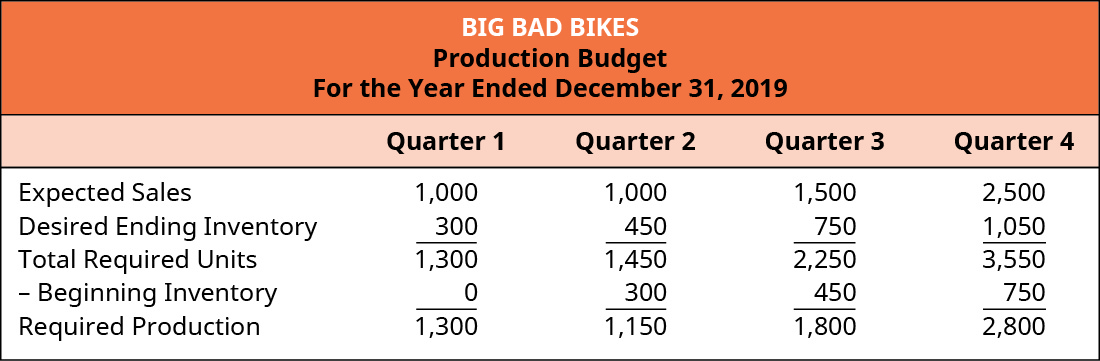

To illustrate the steps in developing a production budget, recall that Big Bad Bikes is introducing a new product that the marketing department thinks will have strong sales. For new products, Big Bad Bikes requires a target ending inventory of 30% of the next quarter’s sales. Unfortunately, they were unable to manufacture any units before the end of the current year, so the first quarter’s beginning inventory is 0 units. As shown in (Figure), sales in quarter 2 are estimated at 1,000 units; since 30% is required to be in ending inventory, the ending inventory for quarter 1 needs to be 300 units. With expected sales of 1,000 units for quarter 2 and a required ending inventory of 30%, or 300 units, Big Bad Bikes needs to have 1,300 units available during the quarter. Since 1,300 units needed to be available and there are zero units in beginning inventory, Big Bad Bikes needs to manufacture 1,300 units, as shown in (Figure)

The ending inventory from one quarter is the beginning inventory for the next quarter and the calculations are all the same. In order to determine the ending inventory in quarter 4, Big Bad Bikes must estimate the sales for the first quarter of the next year. Big Bad Bikes’s marketing department believes sales will increase in each of the next several quarters, and they estimate sales as 3,500 for the first quarter of the next year and 4,500 for the second quarter of the next year. Thirty percent of 3,500 is 1,050, so the number of units required in the ending inventory for quarter 4 is 1,050.

The number of units needed in production for the first quarter of the next year provides information needed for other budgets such as the direct materials budget, so Big Bad Bikes must also determine the number of units needed in production for that first quarter. The estimated sales of 3,500 and the desired ending inventory of 1,350 (30% of the next quarter’s estimated sales of 4,500) determines that 4,850 units are required during the quarter. The beginning inventory is estimated to be 1,050, which means the number of units that need to be produced during the first quarter of year 2 is 3,800.

The number of units needed to be produced each quarter was computed from the estimated sales and is used to determine the quantity of direct or raw material to purchase, to schedule enough direct labour to manufacture the units, and to approximate the overhead required for production. It is also necessary to estimate the sales for the first quarter of the next year. The ending inventory for the current year is based on the sales estimates for the first quarter of the following year. From this amount, the production budget and direct materials budget are calculated and flow to the operating and cash budget.

Preparing a direct materials budget

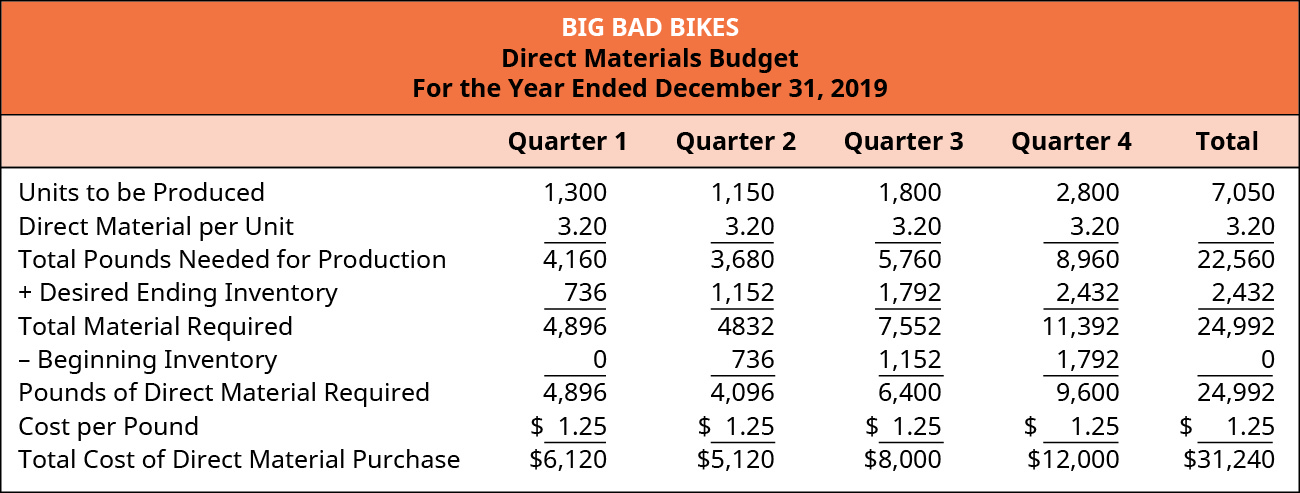

From the production budget, management knows how many units need to be produced in each budget period. Management is already aware of how much material it needs to produce each unit and can combine the direct material per unit with the production budget to compute the direct materials budget. This information is used to ensure the correct quantity of materials is ordered and the correct amount is budgeted for those materials.

Similar to the production budget, management wants to have an ending inventory available to ensure there are enough materials on hand. The direct materials budget illustrates how much material needs to be ordered and how much that material costs. The calculation is similar to that used in the production budget, with the addition of the cost per unit.

If Big Bad Bikes uses 3.2 pounds of material for each trainer it manufactures and each pound of material costs $1.25, we can create a direct materials budget. Management’s goal is to have 20% of the next quarter’s material needs on hand as the desired ending materials inventory. Therefore, the determination of each quarter’s material needs is partially dependent on the following quarter’s production requirements. The desired ending inventory of material is readily determined for quarters 1 through 3 as those needs are based on the production requirements for quarters 2 through 4. To compute the desired ending materials inventory for quarter 4, we need the production requirements for quarter 1 of year 2. Recall that the number of units to be produced during the first quarter of year 2 is 3,800. Thus, quarter 4 materials ending inventory requirement is 20% of 3,800. That information is used to compute the direct materials budget shown in (Figure).

Management knows how much the materials will cost and integrates this information into the schedule of expected cash disbursements, which will be shown in the section on cash budgets. This information will also be used in the budgeted income statement and on the budgeted balance sheet. With 6,000 units estimated for sale, 3.2 pounds of material per unit, and $1.25 per pound, the direct materials used represent $24,000 of the cost of goods sold. The remaining $7,240 is included in ending inventory as units completed and raw material.

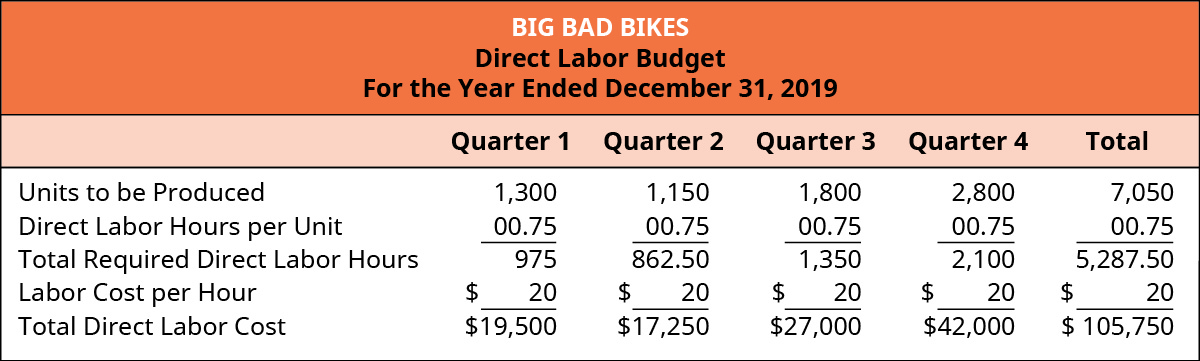

Preparing a direct labour budget

Management uses the same information in the production budget to develop the direct labour budget. This information is used to ensure that the proper amount of staff is available for production and that there is money available to pay for the labour, including potential overtime. Typically, the number of hours is computed and then multiplied by an hourly rate, so the total direct labour cost is known.

If Big Bad Bikes knows that they need 45 minutes or 0.75 hours of direct labour for each unit produced, and the labour rate for this type of manufacturing is $20 per hour, the computation for direct labour simply begins with the number of units in the production budget. As shown in (Figure), the number of units produced each quarter multiplied by the number of hours per unit equals the required direct labour hours needed to be scheduled in order to meet production needs. The total number of hours is next multiplied by the direct labour rate per hour, and the labour cost can be budgeted and used in the cash disbursement budget and operating budget illustrated in Prepare Financial Budgets.

The direct labour of $105,750 will be apportioned to the budgeted income statement and budgeted balance sheet. With 0.75 hours of direct labour per unit and $20 per direct labour hour, each unit will cost $15 in direct labour. Of the 7,050 units produced, 6,000 units will be sold, so $90,000 represents the labour portion of the cost of goods sold and will be shown on the income statement, while the remaining $15,750 will be the labour portion of ending inventory and will be shown on the balance sheet.

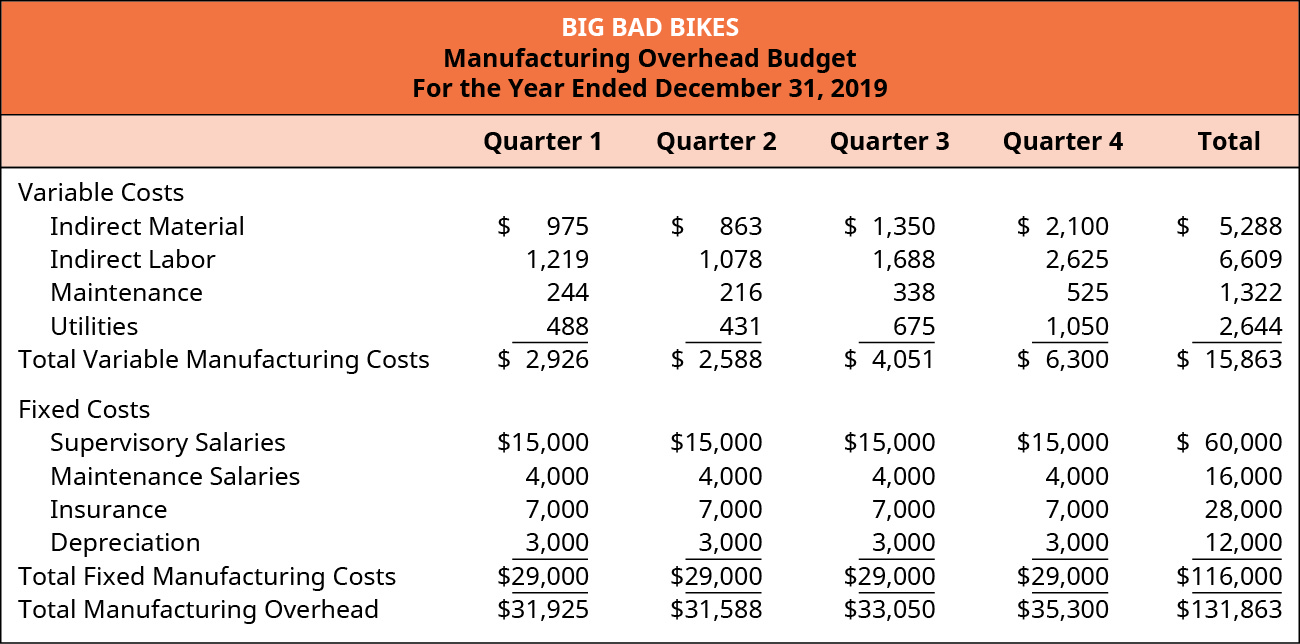

Preparing the overhead budget

The manufacturing overhead budget includes the remainder of the production costs not covered by the direct materials and direct labour budgets. In the manufacturing overhead budgeting process, producers will typically allocate overhead costs depending upon their cost behavior production characteristics, which are generally classified as either variable or fixed. Based on this allocation process, the variable component will be treated as occurring proportionately in relation to budgeted activity, while the fixed component will be treated as remaining constant.

For Big Bad Bikes to create their manufacturing overhead budget, they first determine that the appropriate driver for assigning overhead costs to products is direct labour hours. The overhead allocation rates for the variable overhead costs are: indirect material of $1.00 per hour, indirect labour of $1.25 per hour, maintenance of $0.25 per hour, and utilities of $0.50 per hour. The fixed overhead costs per quarter are: supervisor salaries of $15,000, fixed maintenance salaries of $4,000, insurance of $7,000, and depreciation expenses of $3,000.

Given the direct labour hours for each quarter from the direct labour budget, the variable costs are the number of hours multiplied by the variable overhead application rate. The fixed costs are the same for each quarter, as shown in the manufacturing overhead budget in (Figure).

The total manufacturing overhead cost was $131,863 for 7,050 units, or $18.70 per unit (rounded). Since 6,000 units are sold, $112,200 (6,000 units × $18.70 /unit) will be expensed as cost of goods sold, while the remaining $19,663 will be part of finished goods ending inventory.

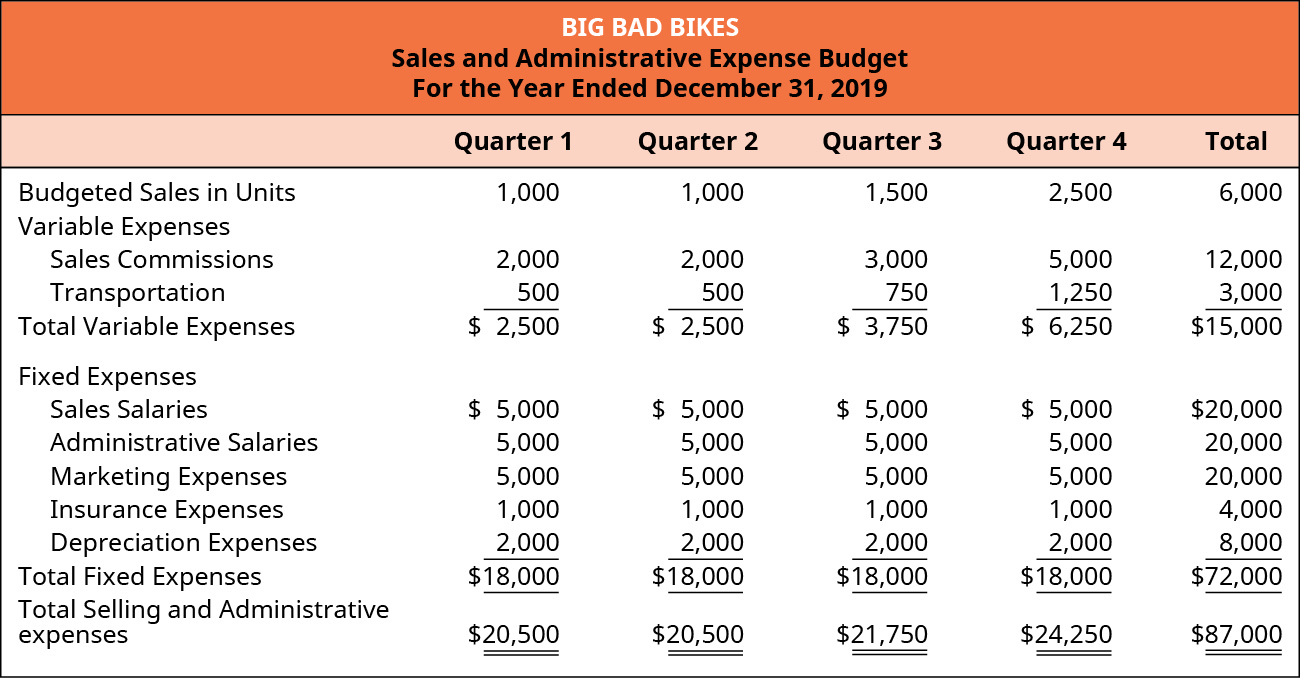

Preparing the selling and administration budget

The direct materials budget, the direct labour budget, and the manufacturing overhead budget plan for all costs related to production, while the selling and administrative expense budget contains a listing of variable and fixed expenses estimated to be incurred in all areas other than production costs. While this one budget contains all nonmanufacturing expenses, in practice, it actually comprises several small budgets created by managers in sales and administrative positions. All managers must follow the budget, but setting an appropriate budget for selling and administrative functions is complicated and is not always thoroughly understood by managers without a background in managerial accounting.

If Big Bad Bikes pays a sales commission of $2 per unit sold and a transportation cost of $0.50 per unit, they can use these costs to put together their sales and administrative budget. All other costs are fixed costs per quarter: sales salaries of $5,000; administrative salaries of $5,000; marketing expenses of $5,000; insurance of $1,000; and depreciation of $2,000. The sales and administrative budget is shown in (Figure), along with the budgeted sales used in the computation of variable sales and administrative expenses.

Only manufacturing costs are treated as a product cost and included in ending inventory, so all of the expenses in the sales and administrative budget are period expenses and included in the budgeted income statement.

Budgeted P&L/income statement

A budgeted income statement is formatted similarly to a traditional income statement except that it contains budgeted data. Once all of the operating budgets have been created, these costs are used to prepare a budgeted income statement and budgeted balance sheet. The manufacturing costs are allocated to the cost of goods sold and the ending inventory. In this introductory text, we will not cover how to create the budgeted income statement because of the complexity surrounding the allocation of cost of goods sold and raw materials inventory. However, for those looking to become accountants, this will be covered in your later studies. It is sufficient to know that all components of our Sales budget, Production budget and Selling and admin budget will form the basis of a budgeted P&L/income statement.